Innovative engineering creates a maintenance-free pole.

Ductile iron was introduced in the 1960s as a modified version of cast iron, which has been used for hundreds of years for products dependent on strength and corrosion resistance. It is produced by adding magnesium alloy to a molten iron of low phosphorus and low sulfur content. The magnesium alloy addition produces a remarkable change in the microstructure by causing the carbon in the iron to assume a spheroidal or nodular shape, compared to the flake form of graphite in gray cast iron, and at the same time producing a finer grained iron matrix in the surrounding ferrite structure.

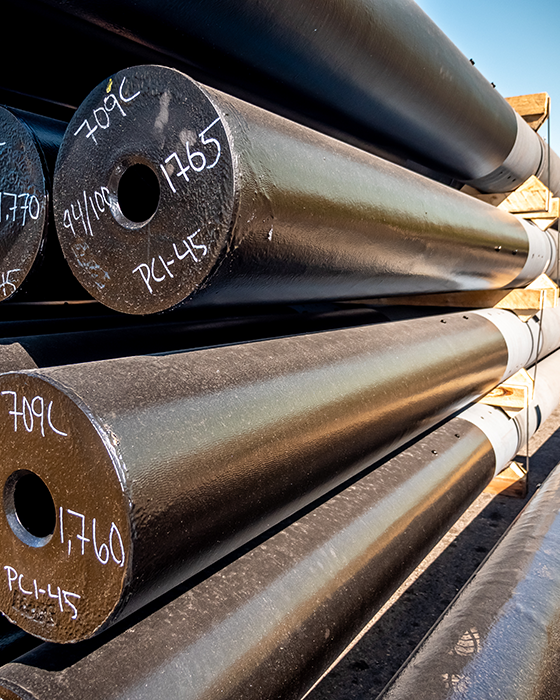

As a result of this remarkable change, a far stronger, tougher, and ductile material is obtained. Ductile iron is only different from cast iron in its ability to bend without breaking under intense load pressure and is resistant to extreme heat, even over extended periods of time. McWane Poles are manufactured by centrifugal casting for consistent strength and dimensional control, and unlike wood, ductile iron doesn’t warp or shrink from wear and weathering.

An innovative coating ensures minimal upkeep.

All of McWane’s poles come with a PermaSafe™ 100 ceramic-epoxy embedment coating that is applied from one foot above the ground line down to the base of the pole, on the inside and outside of the pole. The ceramic-epoxy coating has been used to protect ductile iron in waste pipe applications for decades. The coating will not undercut or peel off, and it is much more robust than urethane coatings.

PermaSafe 100 Ceramic Epoxy is a solvent-free, immersion-grade lining incorporating ceramic pigment into an amine-cured epoxy resin for maximum corrosion protection of steel and concrete substrates immersed in sewage or exposed to other aggressive environments. PermaSafe 100 is a unique and outstanding barrier coating formulated for the protection of steel and concrete in corrosive environments.

Thanks to the unique, resistant properties of PermaSafe 100 ceramic-epoxy coating, ductile iron poles from McWane Poles are not susceptible to the environmental factors that cause other types of poles to need constant maintenance.

Installation is as simple as it gets.

Ductile iron poles are lightweight and pre-drilled, and many poles can be shipped fully assembled and others can be shipped in just 2 pieces and assembled by hand with chain hoists, making them easy to install without heavy machinery.

Unlike wood poles, there is no need to tighten hardware. While our team was visiting Tri-County Electric Cooperative in Hooker, OK, they mentioned that they have issues with hardware on wood poles due to shrinkage of the pole over time. As part of their initial trial, they did not believe the ductile iron poles wouldn’t shrink as well. One year from the date of the first install, however, they checked the hardware and found they were just as they had been installed on day one, and there was no need for them to tighten any of the hardware.

In addition, unlike galvanized steel, there is no need to treat holes drilled in the field. Steel poles are often treated with a zinc galvanization to provide additional corrosion protection versus weathering steel poles. If holes are drilled in the field, the steel that is below the galvanization is exposed. These holes must be treated with a rust inhibiting coating to prevent accelerated corrosion at the drill location. If the holes are not treated properly, the steel will corrode between the galvanized coating on the interior and exterior surface.

A long lifespan means less maintenance.

The strength, durability, and highly resistant properties of ductile iron gives our poles an expected service life of more than 75 years. Ductile iron has a service life comparable to steel and twice as long as wood. And because ductile iron is corrosion-resistant and has a low-maintenance requirement, McWane Poles have a lower life-cycle cost than steel or concrete alternatives.

Why do other materials require more maintenance?

Over time, poles are subjected to various forces, including decay, pests, and weather. Exposure to moisture from driving rain, whipping winds, and flash floods can cause significant damage to materials, which is why a 30 year lifespan is considered long for wood poles, compared to an average lifespan of 75+ years for ductile iron.

Maintenance practices for poles differ from owner to owner, but a survey of more than 200 American utility providers conducted by the Forest Product Journal found that maintenance and upkeep is a significant factor in constant pole replacement. For instance, carpenter ants are a problem that is not typically treated. 61% of those surveyed said they did not have any specific treatment for carpenter ant control and opted to replace poles once damaged.

Inspection is minimal, too.

Wood poles require additional inspection, which are are often contracted out to a consultant and can be costly. Unlike wood, a visible inspection of ductile iron will let the user know if any further analysis is needed. If the pole above ground and the embed coating at ground level looks good, then there is no need to do additional analysis. In fact, our ductile iron poles only need to be visually inspected every 10 years.

Set it and forget it.

Ductile iron poles give you one less thing to worry about. Because of its strength and composition, ductile iron is highly resistant to wind, storms, and heat from wildfires, as well as completely resistant to rot, insects, freezing weather, and woodpeckers. Maintenance and upkeep are minimal to none, which is why we call it “set it and forget it.”