Utility poles are the unsung heroes of our nation’s electrical and communication networks. They support the lines that power homes, businesses, and essential services, ensuring communities remain connected and functional. Without them, modern life as we know it would come to a standstill.

When these poles exhibit signs of wear or damage, utility companies—including larger power companies, rural electric co-ops, and municipalities—face a critical question: is it better to repair or replace a utility pole? The decision has significant implications for operational efficiency, safety, cost management, and environmental stewardship.

Factors To Consider When Deciding

Making an informed decision between repairing or replacing a utility pole involves evaluating several key factors. Each aspect determines the most prudent course of action to ensure safety, compliance, and cost-effectiveness.

Age of the Utility Pole

The age of a utility pole significantly impacts its structural integrity and expected lifespan. Designers intend poles to last for decades, though exposure to harsh weather conditions accelerates deterioration. Older poles may suffer from internal decay, wood rot, or material fatigue that isn’t immediately visible. For example, a wooden pole installed 40 years ago may have weakened due to an insect infestation or moisture penetration.

While not all older poles will need replacement, age makes them more likely to have damage. Assessing the pole’s age helps you determine whether a repair can effectively extend its service life or if replacement is a more viable long-term solution.

Extent of Damage

Evaluating the extent of damage is essential in the decision-making process. Techniques such as reinforcement with steel trusses or preservative treatments are perfect for fixing minor damages, such as small cracks, surface abrasions, or areas of decay.

For instance, a pole with superficial cracks can continue to serve safely with reinforcements. However, extensive damage—such as large splits, severe rot, or structural compromise from vehicle collisions or natural disasters—can render a pole unsafe and necessitate replacement.

Cost Analysis

A thorough cost analysis compares the immediate repair expenses with the long-term costs associated with replacement. While repairs often present lower upfront costs, they may lead to recurring expenditures if the pole continues to deteriorate or requires frequent maintenance. For example, repairing a pole might cost a few hundred dollars, but repeated repairs over several years can exceed the cost of a new pole.

Replacement involves a higher initial investment but can offer cost savings over time due to reduced maintenance needs and improved reliability. A life-cycle cost analysis helps utility companies, with expertise from power pole suppliers like McWane Poles, identify the most economically advantageous option in the long run.

Safety Concerns

Safety is a paramount consideration for utility companies. A compromised utility pole poses significant risks to utility workers and the public. Structural failure can lead to power outages, property damage, injuries, and fatalities.

For example, a failing pole could collapse onto a roadway, causing accidents or interrupting critical services. Ensuring all poles meet rigorous safety standards protects the company from liability and fosters public trust. If a pole’s condition raises safety concerns that repairs cannot address, replacement is often the safest and most responsible choice.

Regulatory Compliance

Utility providers must comply with industry regulations and standards from organizations like the Occupational Safety and Health Administration (OSHA) and the National Electrical Safety Code (NESC). Regulations may dictate specific conditions under which a pole must be replaced rather than repaired.

Benefits of Repairing a Utility Pole

Repairing a utility pole offers several advantages, particularly when dealing with minor damages or when budget constraints are significant.

Firstly, you can complete repairs faster and minimize disruptions to electrical services. The lower upfront repair costs for rural electric co-ops and municipalities with limited resources make this option more feasible.

Secondly, repairing extends the life of existing infrastructure and maximizes the value of initial investments. Techniques such as installing steel reinforcement bands, applying protective coatings, or using wood preservatives can restore a pole’s structural integrity.

Thirdly, repair work often requires less labor and equipment than replacement. Less complex projects allow utility companies to allocate resources to other critical areas, enhancing overall operational effectiveness.

Moreover, repairing supports environmental sustainability by reducing waste. Extending the life of existing poles minimizes the need for new materials and the environmental impact associated with manufacturing and transporting new poles.

Lastly, repairing can be a strategic choice in emergencies. Quick repairs can restore services faster than scheduling a full replacement—repairs like these can be vital during natural disasters or unexpected outages.

Benefits of Replacing a Utility Pole

Although replacing a utility pole involves higher initial costs, the long-term benefits can outweigh the immediate expenses. One primary advantage is enhanced safety and reliability.

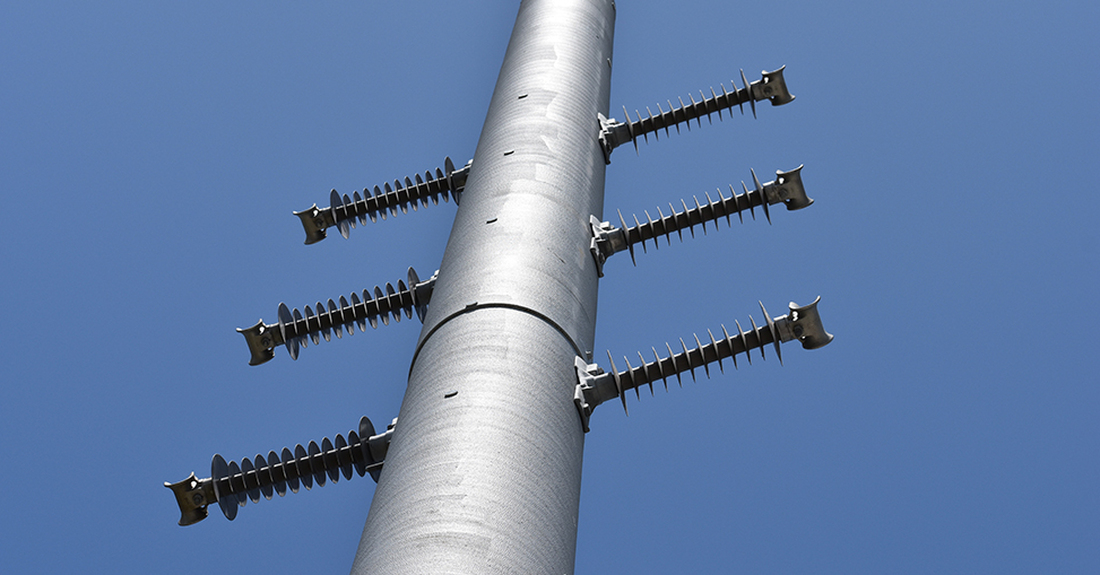

New poles constructed with modern, sustainable materials like ductile iron, offer superior strength and durability. Newer materials resist environmental degradation better than traditional wood poles.

Replacement also allows for the integration of new technologies and infrastructure upgrades. For example, new poles can support higher load capacities, accommodate additional lines, or include features for smart grid applications. Flexibility is a goal for larger electric power companies aiming to modernize their networks and meet increasing energy demands.

New poles require less maintenance, leading to cost savings over time. Less need for repairs and inspections frees up resources for other initiatives, improving overall efficiency.

Additionally, replacing poles can improve environmental outcomes. Modern materials such as ductile iron offer better environmental performance, such as being recyclable at the end of their service life or having a lower overall environmental footprint during production.

Lastly, replacement allows for standardizing equipment across the network, simplifying maintenance and training. Uniformity in infrastructure can lead to efficiencies in operations and supply chain management.

Environmental Impact

Repairing utility poles contributes to waste reduction by prolonging the life of existing materials. An environmental approach conserves natural resources and reduces the environmental impacts of manufacturing and transporting new poles. It aligns with sustainability goals and demonstrates a commitment to environmental stewardship.

Conversely, replacing poles offers an opportunity to utilize eco-friendly materials. Modern poles made from sustainable resources or recyclable materials, such as steel or ductile iron, have a longer lifespan and are easier to recycle at the end of their use. Better material choice reduces long-term environmental impacts and supports a circular economy.

Utility companies must evaluate the environmental implications of both options. Considering factors such as carbon footprint, resource consumption, and waste generation helps companies make decisions that align with environmental regulations and corporate sustainability objectives.

Moreover, newer pole designs minimize environmental disruption during installation. For example, using direct embedment methods reduces the need for extensive excavation, preserving surrounding ecosystems.

Picking the Best Choice

The question of whether it’s better to repair or replace a utility pole does not have a one-size-fits-all answer. Utility companies must carefully assess factors such as the pole’s age, extent of damage, cost implications, safety concerns, and regulatory requirements. Balancing these considerations ensures that the decision supports operational efficiency, safety, and long-term reliability.

For utility providers seeking durable and innovative solutions, McWane Poles offers high-quality products with designs and materials that meet the evolving needs of the energy sector. Our poles provide strength, reliability, and sustainability, enhancing your infrastructure and supporting your commitment to excellence. Contact us today to learn how we can assist you in building a stronger, more reliable network.