Back in early 2021, the United States Environmental Protection Agency (EPA) proposed to ban all uses of the wood preservative pentachlorophenol. The decision came after the sole producer of the chemical in North America announced that it was shutting down its pentachlorophenol manufacturing facility by the end of 2021.

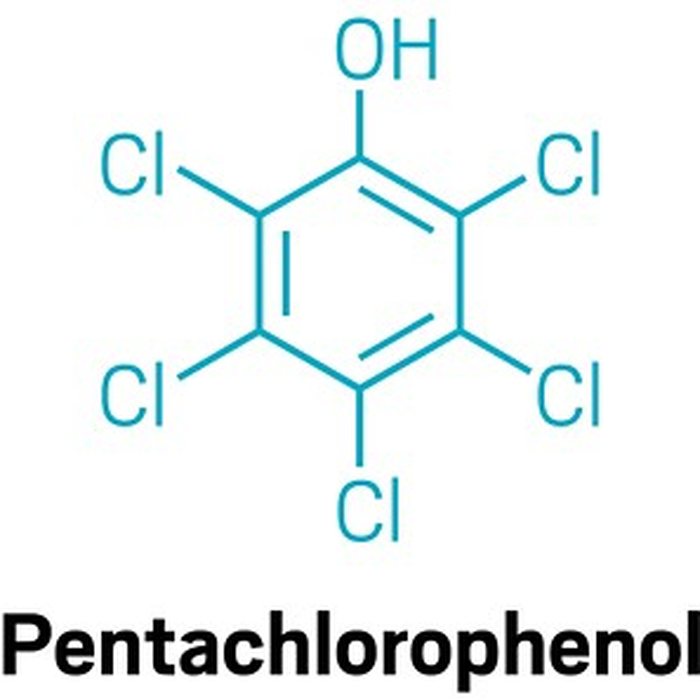

Environmental groups have been urging the EPA to ban pentachlorophenol for over 20 years. Typically referred to as ‘penta’, the chemical is used primarily to treat wood utility poles. The US National Toxicology Program lists pentachlorophenol as a human carcinogen. The chemical has been banned under the United Nation’s Stockholm Convention on Persistent Organic Pollutants.

The EPA claims that pentachlorophenol poses significant human health risks to workers and those that come in contact with it. To address this risk, the agency has since prohibited all uses by canceling its registration under the federal pesticide law. Safer alternatives, such as copper naphthenate and dichloro-octyl-isothiazolinone, and other wood preservatives, such as chromated arsenicals and creosote, are available in the marketplace.

Pentachlorophenol (PCP) is an industrial wood preservative used mainly to treat utility poles and cross arms.

Because pentachlorophenol is cheap and an effective preservative, approximately half of the wood poles in the US are treated with it. With the phase out of penta and the usage of stockpiled material, we still see some utility poles treated with it that are still available. However, it is dwindling fast and many utility companies around the country are scrambling to find suitable replacements. Another issue has been what to do with the treated poles when they are replaced.

Please consider McWane Poles as your choice moving forward. Made from 96% recycled scrap metal and 100% recyclable at the end of its service life, see how these durable, eco-friendly poles are a groundbreaking alternative to conventional wood poles. Unlike pentachlorophenol and other wood pole treatments, ductile iron is impermeable to organic contaminants, protecting clean water from potential toxic environmental spills. McWane’s ceramic-epoxy embedment coating is certified by the National Sanitation Foundation (NSF) to be safe for use in contact with potable water sources.

Here are some product benefits and features of McWane ductile iron poles:

LOW LIFE-CYCLE COSTS. Ductile iron poles have a service life of 75+ years, outlasting other materials.

LOW MAINTENANCE. Strong, lightweight, and resistant to rot, insects, and woodpeckers.

CONSISTENT STRENGTH. Ductile iron poles are engineered with a minimum yield strength of 42ksi.

SIMPLE INSTALLATION. The round, tapered design simplifies orientation for installers, and these can easily field drilled.

CONSISTANT APPEARANCE. Ductile iron poles are manufactured by centrifugal casting, with consistent dimensional control and will not warp over time like wood.

To learn more about using McWane Poles as a possible solution for your direct embed needs for distribution or transmission applications, please contact your Regional Sales Manager for more information.

Please view the Pentachlorophenol Webinar below for more information.